PRODUCTSIntroduction to Test Machines

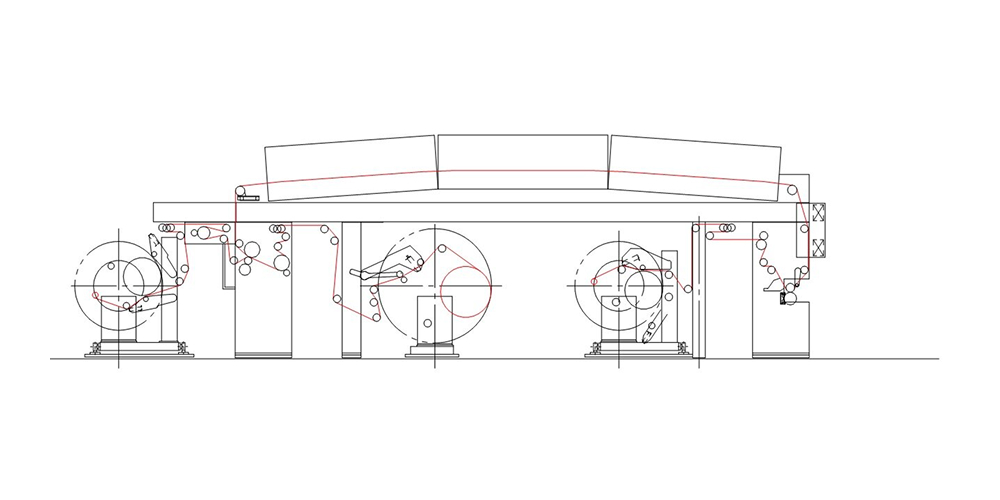

Test Machine 1

Specifications

| Coating Method |

Interchangeable coating method |

|---|---|

| Substrate Width | 100–1150mm |

| Substrate Transport Speed | 1–300m/min |

| Drying / Curing Method |

Hot Air Drying MAX 110℃ 2.7m × 3 Zones UV (Ultraviolet) Curing |

| Unwinding Unit | Two-shaft turret type (Max roll diameter 600mm) |

| Rewinding Unit | Two-shaft turret type (Max roll diameter 800mm) |

Our thin-film coating specialists use various measuring instruments to resolve coating liquid and coating process issues.

Our engineers with specialized knowledge of coating liquids are ready to assist. We bring together our technical expertise to fully support our customers.

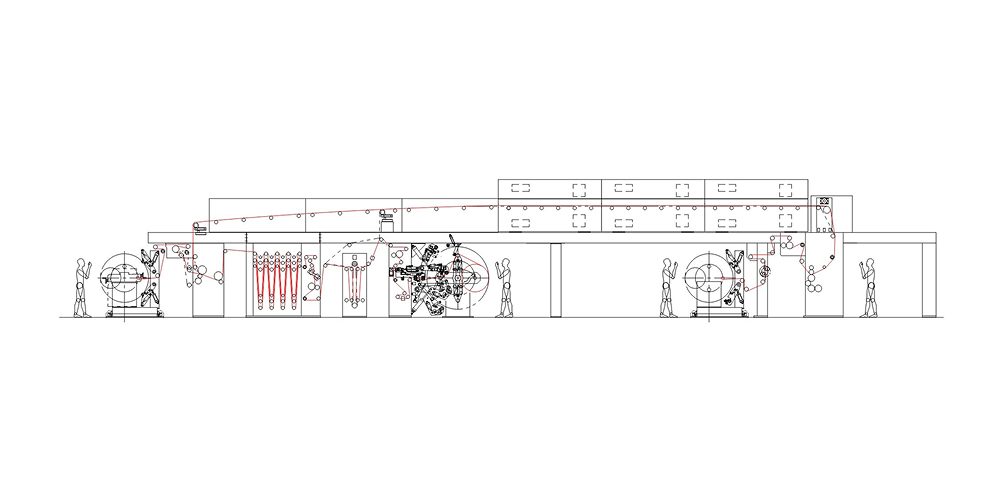

Test Machine 2

Specifications

| Coating Method | |

|---|---|

| Substrate Width | 500–1150mm |

| Guide Roll Width | 1200mm |

| Substrate Transport Speed |

200m/min (3-inch core) 300m/min (6-inch core) |

| Unwinding Unit | Two-shaft turret type (Max roll diameter 600mm) |

| Rewinding Unit |

Two-shaft turret type (Max roll diameter 800mm) Tapeless System |

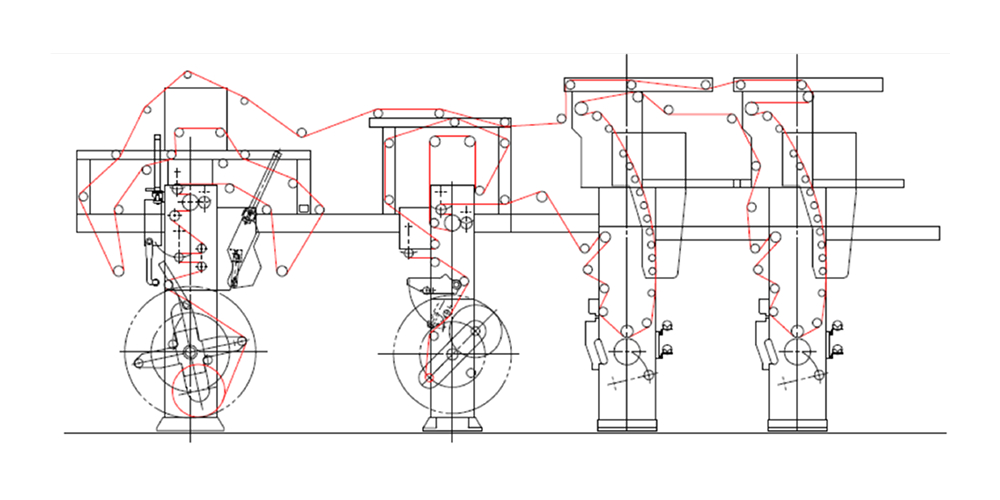

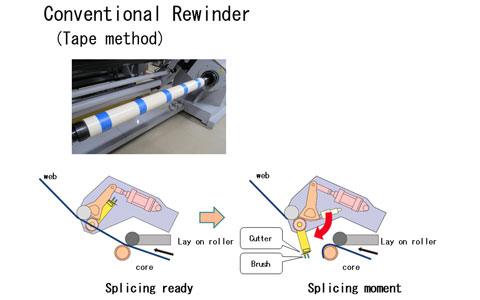

The conventional tape-based rewinding method involved wrapping adhesive tape around the core beforehand (as shown in Photo 2), then pressing the web against it with a pressure roller. A cutter blade would cut the web slightly downstream, and the cut end would be pressed against the core with a brush to start the new rewind.

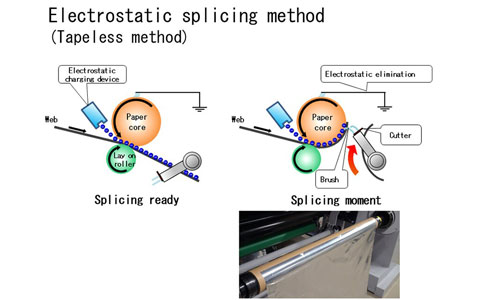

Our newly developed tapeless rewinding device consists of a web-cutting cutter, brush, rewind core, static charging device, static eliminator bar, and pressure roller.

First, the rewinding turret is prepared for splicing. The static charging device then moves into position. Once in place, the web and core are charged for a set time. Next, the web is cut by the cutter, and the brush behind the cutter presses the web against the core, allowing it to adhere through static electricity. The rewinding process on the new core begins, and at the same time, the static electricity on the core is discharged. This sequence enables splicing without using tape, utilizing static electricity instead.

Test Machine 3

Specifications

| Coating Method | |

|---|---|

| Colors | 2 colors, single-sided |

| Substrate Width | 600–1250mm |

| Guide Roll Width | 1300mm |

| Substrate Transport Speed | 200m/min |

| Drying / Curing Method |

Hot Air Drying MAX 80℃ 9 Nozzles, Air Volume 60㎡/min |

| Unwinding Unit | Two-shaft turret type (Max roll diameter 600mm) |

| Rewinding Unit | Two-shaft turret type (Max roll diameter 800mm) |