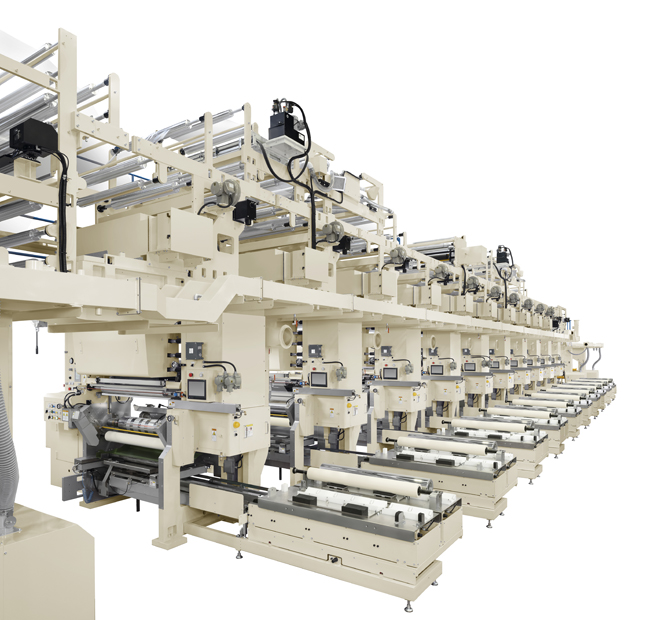

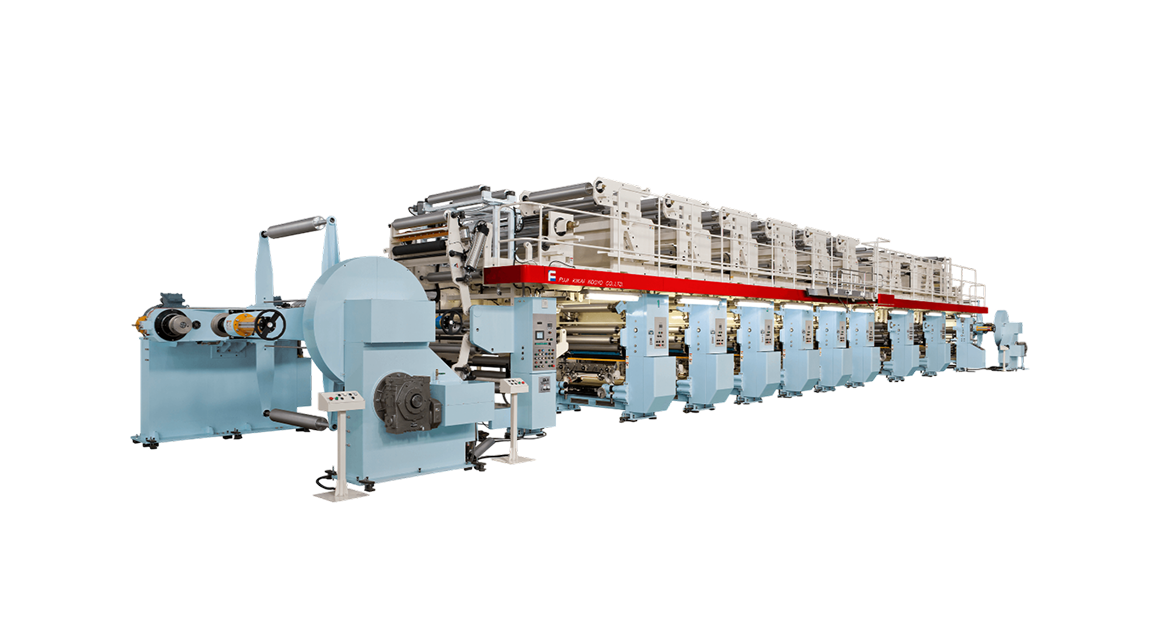

PRODUCTS Rotogravure Printing Machines

FSR Series Film Applications

A future where people can thrive through automation! Our flagship model achieves shorter setup times and reduced workload with plate cylinder automatic exchange and comprehensive automation built on that foundation.

Product Features

-

Automatic Plate Cylinder Exchange

If the next job’s plate cylinder is loaded on the new-cylinder cart on the non-operator side with the keyway facing downward using the dedicated jig, the machine will automatically exchange the cylinder in about 4 minutes.

In addition to reducing operator workload, automatic exchange lets operators work on other tasks during changeover, contributing to shorter setup times.

-

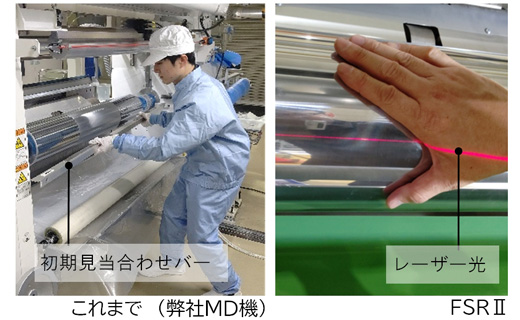

With a laser marker

No need for initial register alignment barsAfter the plate cylinder is installed, a laser line is automatically projected onto the plate surface, eliminating the operation of placing alignment bars.

-

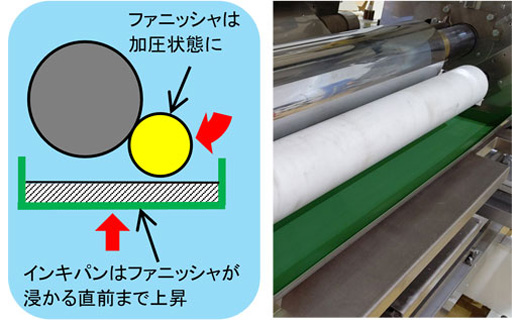

One-push button

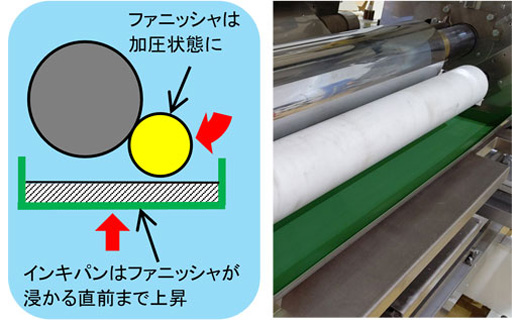

Ink Pan PresetWith a single push, the ink pan is electrically raised to the set position and the furnisher is pressurized.

-

option

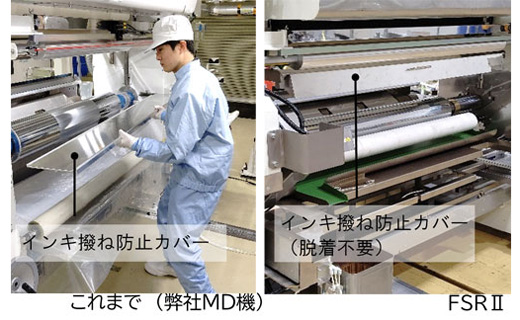

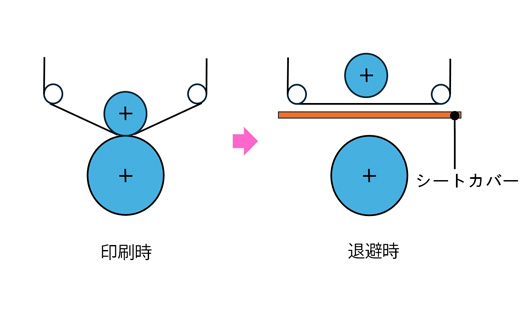

No need to attach/detach the anti-splash ink cover

The anti-splash ink cover retracts together with the impression roll, so attaching and detaching are unnecessary. Slide it into place when needed.

-

option

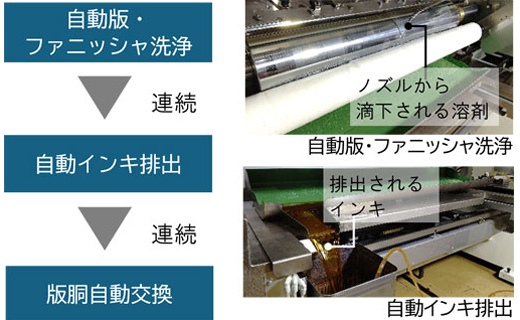

With one push before the automatic cylinder exchange

Automatic plate & furnisher cleaning, automatic ink dischargeAfter automatic plate/furnisher cleaning and automatic ink discharge are completed, the system proceeds automatically to the plate cylinder exchange.

Standard Specifications

| Substrate | Plastic film | Machine Speed | 250 m/min |

|---|---|---|---|

| Cylinder Width | 1300 mm | Cylinder Circumference Length | 400–800 mm |

| Cylinder Center Height | 1050 mm | Unwind/Rewind Diameter | ⌀600, ⌀800 mm |

Videos

-

FSRⅡ Overview

-

FSRⅡ — Automatic Changeover (Lab Machine)

-

FSRⅡ — Automatic Changeover (Example)

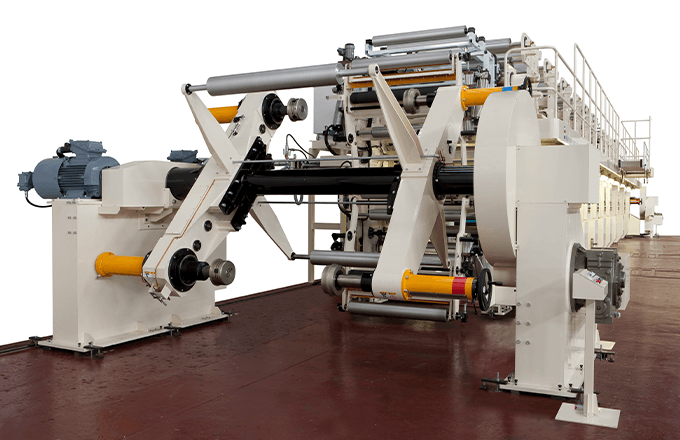

FTS Series Film Applications

A model co-developed with converters as a countermeasure to 3K (hard, dirty, dangerous) conditions on the shop floor!

Centered on the Speedy Arm, its diverse functions help reduce operator workload.

Product Features

-

Effortless one-person

Speedy Arm for plate cylinder exchangeAs a pneumatic assist device, it enables easy cylinder exchange with light force.

The rotatable table can hold two cylinders, allowing removal and installation in one operation.

-

Lightweight and easy-to-exchange

Sleeve-type impression rollThe impression roll can be exchanged easily with light force. Once removed, cleaning becomes simple, which is effective when thorough cleaning is required for water-based printing.

-

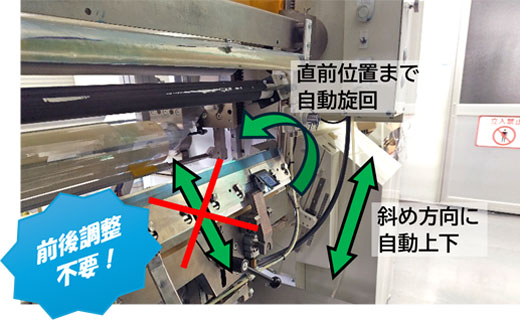

Automatic height setting

Doctor PresetThe doctor automatically moves to the height appropriate for the cylinder diameter and swings to just before the operating position.

It moves up and down diagonally, eliminating the need for fore-aft adjustment.

-

One-push button

Ink Pan PresetWith a single push, the ink pan is electrically raised to the set position and the furnisher is pressurized.

-

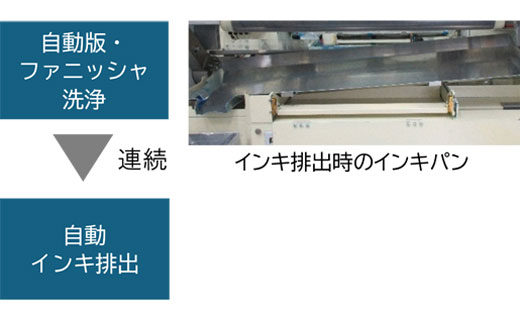

One-push button

Automatic plate/furnisher cleaning & automatic ink dischargeAfter automatic plate/furnisher cleaning, the system automatically proceeds to automatic ink discharge.

-

Audio guidance

that tells you the next taskVoice prompts guide the next task, supporting operators with less experience.

Standard Specifications

| Substrate | General plastic film | Machine Speed | 250 m/min |

|---|---|---|---|

| Cylinder Width | 1,300 mm | Cylinder Circumference Length | 400–900 mm |

| Cylinder Center Height | 930 mm | Unwind/Rewind Diameter | ⌀600, ⌀800 mm |

Videos

-

Plate & Furnisher Roll Cleaning

-

Plate & Furnisher Roll Exchange

-

Doctor Replacement & Setup

-

End-to-End Changeover Sequence

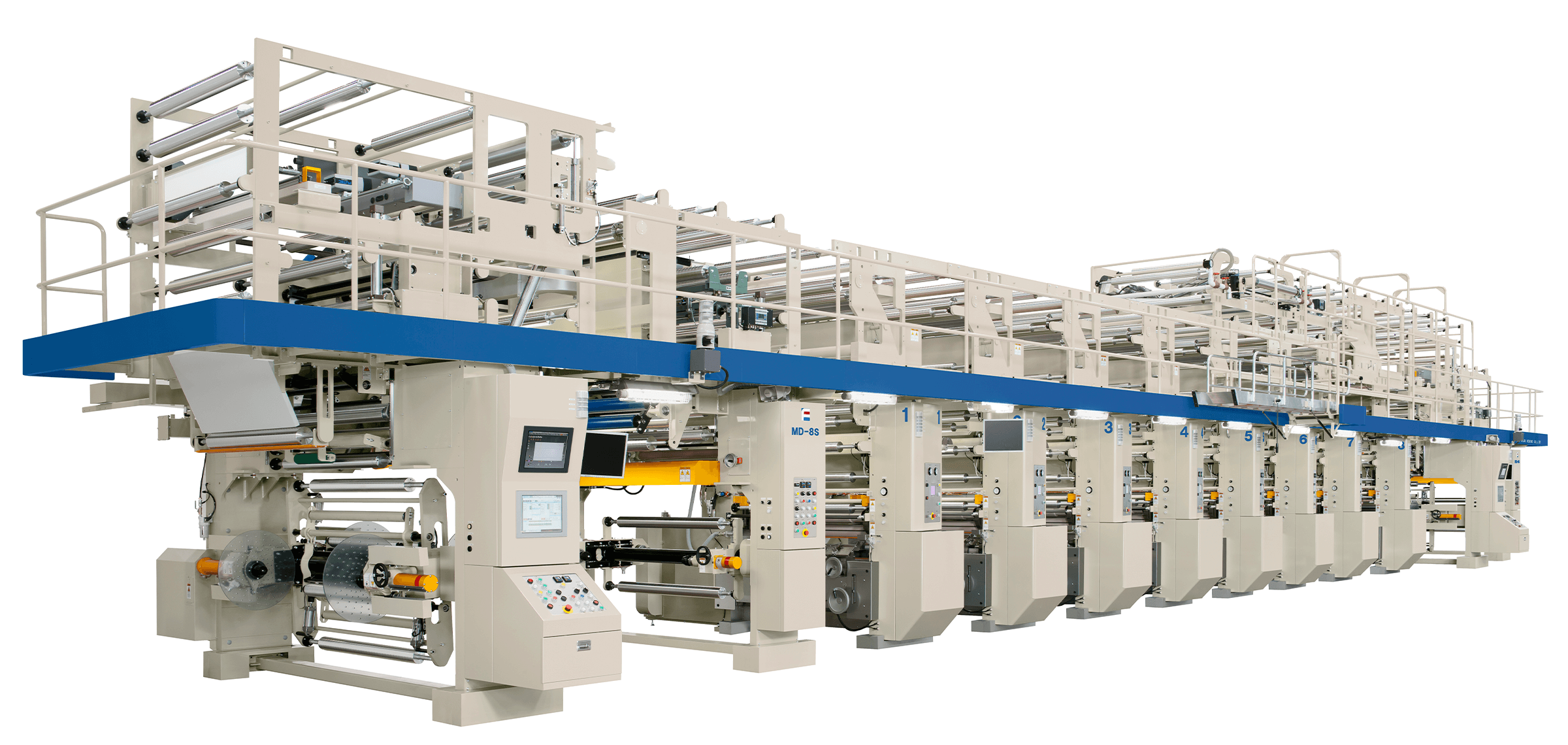

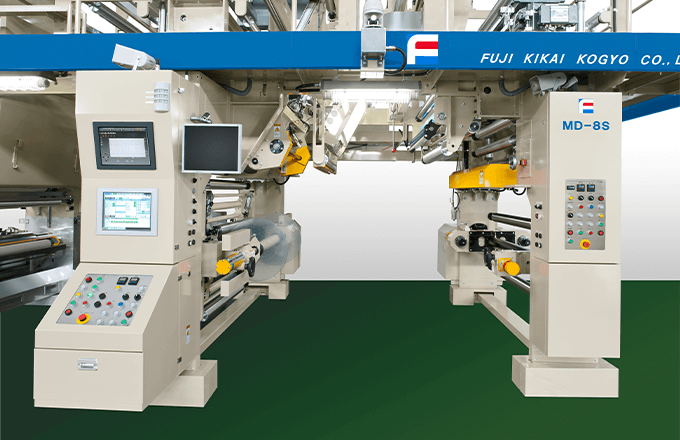

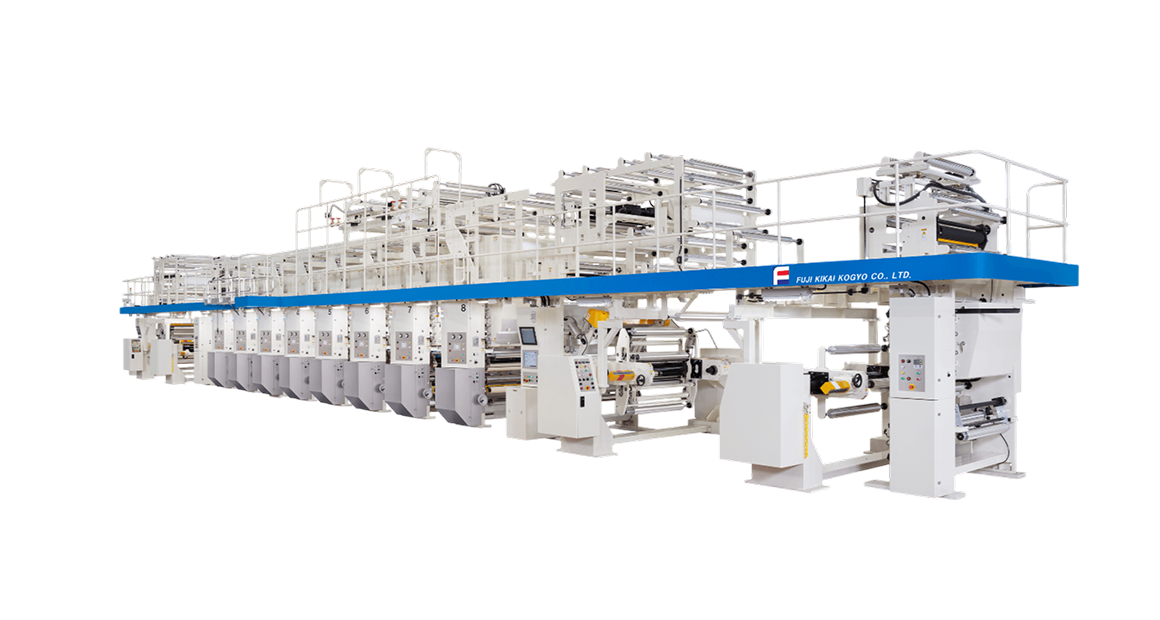

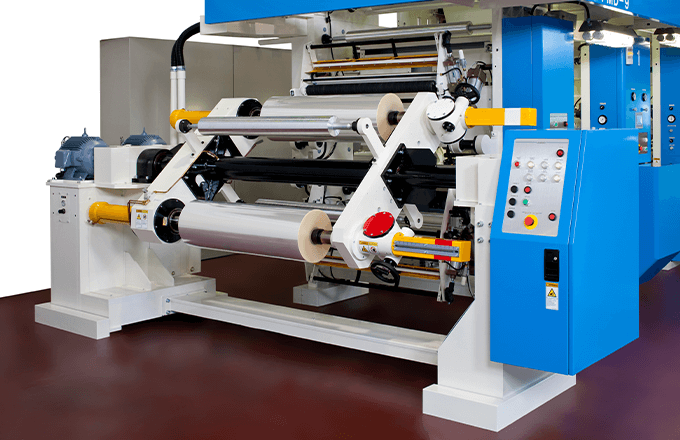

MD Series Film Applications

A high-spec long-seller that continues to evolve with proven trust and performance!

Leveraging decades of know-how, we create added value for your products.

Product Features

-

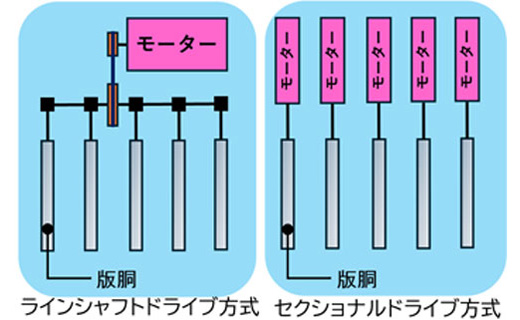

High register accuracy

with independent plate-cylinder motorsBy moving from traditional line-shaft drive to a sectional drive with independent motors per unit, highly synchronized operation with minimal gear backlash becomes possible. Pre-setup on idle units during production is also supported, contributing to improved operating rates.

-

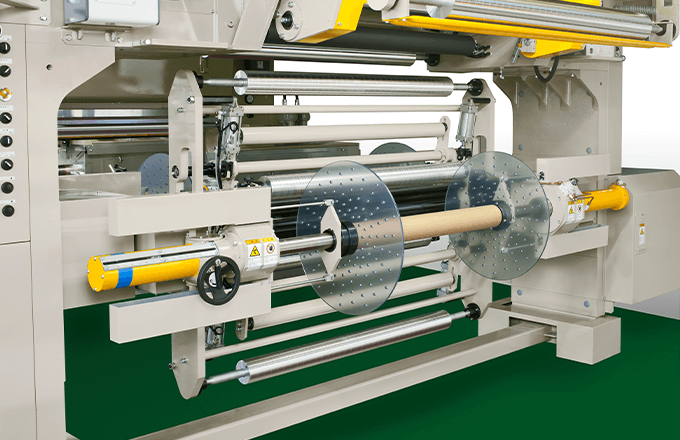

Easy skip printing

thanks to impression-roll retractionRetracting the impression roll prevents the impression rubber from contacting the substrate, ensuring high register accuracy even with skip printing.

Sheet covers also make changeover on idle units easy and safe.

-

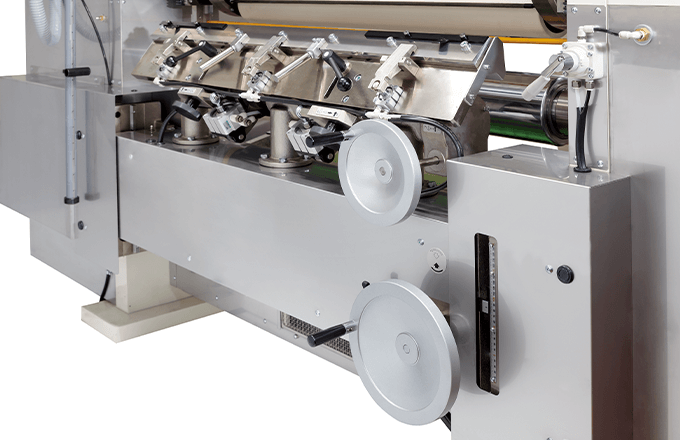

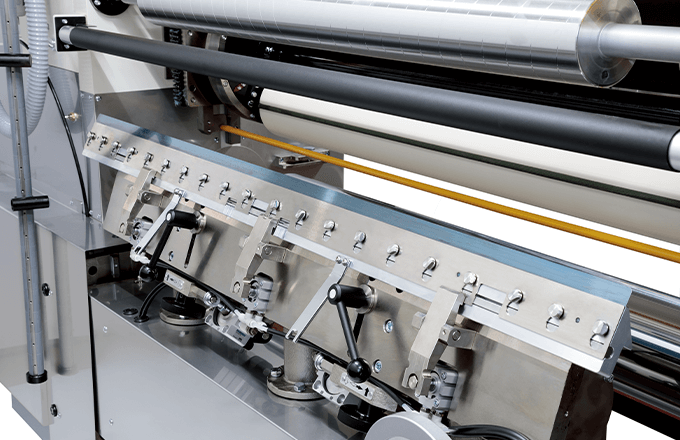

High-rigidity doctor

that minimizes doctor-related issuesThe “Fuji Box Doctor,” with greatly increased rigidity and reduced vibration, mitigates defects such as plate flooding and doctor streaks. Water-based printing is also supported.

-

Remote maintenance

enabling fault diagnosis from afarIn the event of a system fault, our service engineers can investigate (and in some cases restore) the system without a site visit, enabling a swift response.

-

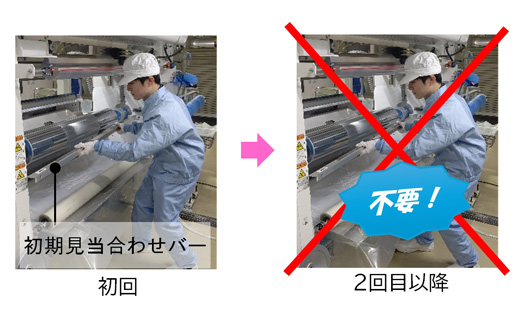

No initial register alignment

for repeat printingOnce initial register alignment is performed for the first run, the saved data can be recalled from the second run onward, allowing immediate production.

Standard Specifications

| Substrate | Plastic film | Machine Speed | 250 m/min |

|---|---|---|---|

| Cylinder Width | 1,300 mm | Cylinder Circumference Length | 400–940 mm |

| Cylinder Center Height | 930, 850 mm | Unwind/Rewind Diameter | ⌀600, ⌀800 mm |

FMD Series Film Applications

An international model recognized worldwide!

Despite specs just below the MD, it’s packed with functions, delivering excellent cost performance.

Product Features

-

High register accuracy

with independent plate-cylinder motorsMoving from traditional line-shaft drive to sectional drive with independent motors per unit enables highly synchronized operation with minimal gear backlash.

-

Reduced waste via ever-advancing tension control

In addition to conventional dancer-roll tension control, feedback control via a tension pickup roll achieves even higher-precision tension control.

-

Remote maintenance

enabling fault diagnosis from afarIn the event of a system fault, our service engineers can investigate (and in some cases restore) the system without a site visit, enabling a swift response.

-

No initial register alignment

for repeat printingOnce initial register alignment is performed for the first run, the saved data can be recalled from the second run onward, allowing immediate production.

-

Extensive options for customization to your needs

Customization is available based on your requirements, such as turn bars and driven cooling rolls.

Standard Specifications

| Substrate | Plastic film | Machine Speed | 240 m/min |

|---|---|---|---|

| Cylinder Width | 1,300 mm | Cylinder Circumference Length | 400–940 mm |

| Cylinder Center Height | 930, 850 mm | Unwind/Rewind Diameter | ⌀600, ⌀800 mm |

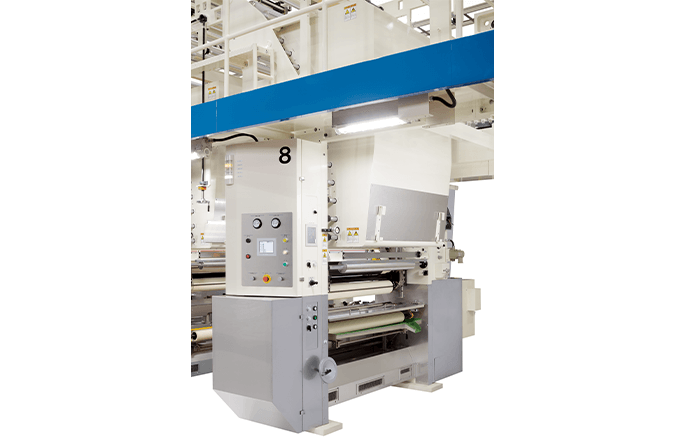

FMS Series Film Applications

A space-saving model that’s compact yet equipped with all essential functions!

Of course, it also supports a wide range of optional specifications.

Product Features

-

Single impression-roll design achieves 2,800 mm unit height

Its compact design can also meet weight restrictions.

-

Easy Operation

Printing conditions can be entered via the touch panel.

-

Extensive options for customization to your needs

Customization is available based on your requirements, such as turn bars, driven cooling rolls, or a three-arm impression roll, and more.

Standard Specifications

| Substrate | Plastic film | Machine Speed | 200 m/min |

|---|---|---|---|

| Cylinder Width | 1,300 mm | Cylinder Circumference Length | 400–940 mm |

| Cylinder Center Height | 800 mm | Unwind/Rewind Diameter | ⌀600 mm |

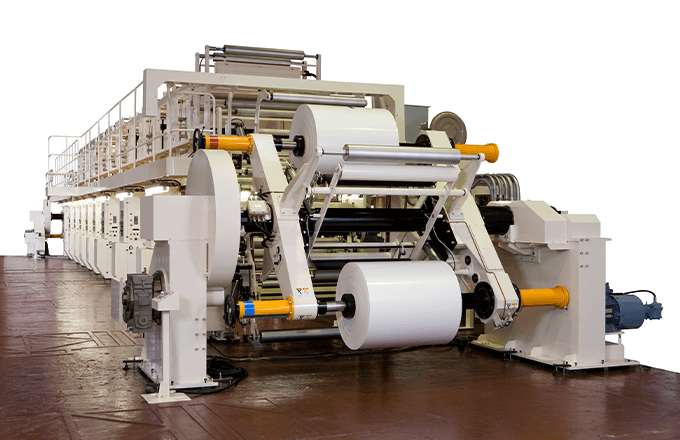

PMD Series For Paper Applications

The PB paper model’s plate-cylinder drive has been upgraded to sectional drive!

While retaining the high-pressure specification, it also incorporates functions from the high-spec MD model.

Product Features

-

High register accuracy

with independent plate-cylinder motorsMoving from traditional line-shaft drive to sectional drive with independent motors per unit enables highly synchronized operation with minimal gear backlash.

Additionally, the drive-side space—previously dead space on conventional machines—can now be utilized effectively. -

Reduced waste via ever-advancing tension control

In addition to conventional dancer-roll tension control, feedback control via a tension pickup roll achieves even higher-precision tension control.

-

Electrostatic printing, high impression pressure

Supports electrostatic printing. The printing section provides a high impression pressure of 20,000 N and is equipped with a backup-roll mechanism to ensure printing stability.

-

Remote maintenance

enabling fault diagnosis from afarIn the event of a system fault, our service engineers can investigate (and in some cases restore) the system without a site visit, enabling a swift response.

-

No initial register alignment

for repeat printingOnce initial register alignment is performed for the first run, the saved data can be recalled from the second run onward, allowing immediate production.

-

Extensive options for customization to your needs

Customization is available based on your requirements, such as turn bars and driven cooling rolls.

Standard Specifications

| Substrate | Paper | Machine Speed | 250 m/min |

|---|---|---|---|

| Cylinder Width | 1,300 mm | Cylinder Circumference Length | 400–940 mm |

| Impression Pressure | 20,000 N | Unwind/Rewind Diameter | ⌀1000 mm |