PRODUCTS Laminators

L5 Series Non-solvent laminator

High performance with an eco-friendly design! Our latest solventless coating model is even easier to use.

FUJI KIKAI KOGYO’s flagship solventless type achieves high uptime, stable coating, and a worker-friendly environment—an eco-conscious laminator delivering non-polluting, high-quality results.

Key Features

-

Winding technology: core-lossless brush-cutter system & constant-torque winding

Reduces wrinkles around the core and prevents telescoping to achieve a beautiful winding appearance.

-

Dramatically reduced winding loss with a near-roll unit

By decreasing entrained air and shortening the web path, it helps prevent telescoping and wrinkles.

-

Handles low-initial-tack adhesives with a super-tension system

Ultra-low tension control down to 5 N prevents curl after lamination.

-

Stable coating via a multi-stage squeeze-roll coating method

Controlling the temperature of each roll ensures adhesive temperature stability and consistent coating quality.

-

Improved cleanability and setup workability

Full opening of all squeeze rolls improves cleanability, and the sleeve-type metering roll reduces workload.

Standard Specifications

| Substrate | General plastic films |

|---|---|

| Substrate width | 1,050 / 1,150 / 1,250 mm |

| Machine speed | Max. 200 / 250 / 300 m/min |

| Coating method | Four-roll squeeze coating |

| Unwind / Rewind diameter | φ600 / φ800 / φ1,000 mm |

FML2 Series Dry Laminator

A high-end model that achieves the pinnacle of reduced winding loss.

Experience clean, high-quality production.

Key Features

-

Stationary splicing with a winding accumulator

Greatly reduces splice failures.

-

About 50% reduction of core loss versus conventional machines (in-house comparison)

A sliding cutter without fold-back at splicing drastically reduces core-area loss.

-

Filter at the air supply section

Prevents foreign matter from entering to maintain quality.

-

Space-saving 3-roll accumulator

Requires less floor space compared with a 2-roll type.

Standard Specifications

| Substrate | General plastic films, aluminum, paper |

|---|---|

| Substrate width | 1,050 / 1,150 / 1,250 mm |

| Machine speed | 220 / 250 m/min |

| Coating method | Gravure direct method, AQ chamber method |

| Unwind / Rewind diameter | φ600 / φ800 / φ1,000 mm |

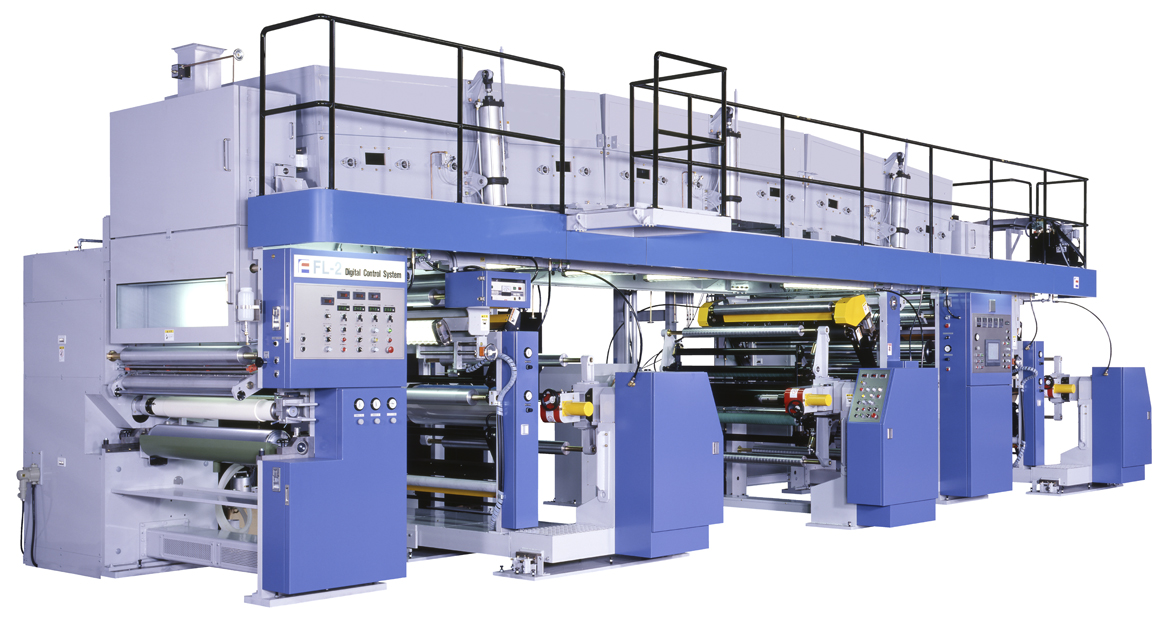

FL2 Series Dry Laminator

An evolved classic that set the global standard for chambered doctors in lamination.

A versatile laminator ideal for confectionery, retort foods, frozen foods, and more.

Key Features

-

Winding technology: core-lossless brush-cutter system & constant-torque winding

Reduces core-area wrinkles and prevents telescoping to achieve a beautiful roll appearance.

-

Dramatically reduced winding loss with a near-roll unit

Less entrained air and shorter web path help prevent telescoping and wrinkles.

-

Improved uptime and safety with a chambered doctor

Suppresses viscosity fluctuation and greatly extends the life of doctor blades and coating rolls. (Solvent usage can be reduced by up to 30% vs. our previous models.)

Standard Specifications

| Substrate | General plastic films, aluminum, paper |

|---|---|

| Substrate width | 1,050 / 1,150 / 1,250 mm |

| Machine speed | 220 / 250 m/min |

| Coating method | Gravure direct method, AQ chamber method |

| Unwind / Rewind diameter | φ600 / φ800 mm |