PRODUCTS Coaters

MCD Micro Chambered Doctor

A coating head developed specifically for thin-film, high-speed coating.

We developed a sealed kiss-reverse type chambered doctor.

Standard Specifications

| Applications | Lithium-ion batteries, flat panel displays, magnetic tape, etc. |

|---|---|

| Coating method | Gravure kiss-reverse method |

| Doctor method | Chambered doctor method |

| Machine speed | 10–300 m/min |

| Substrate width | Max. 2650 mm |

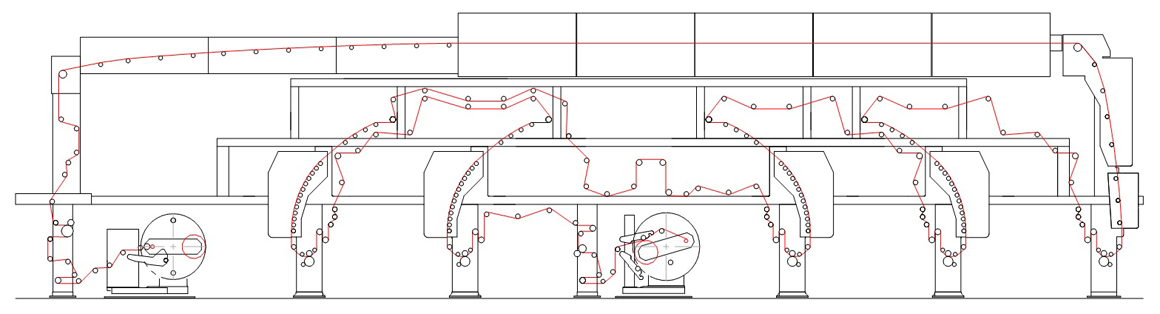

C7-130 Lithium-ion Battery Applications

Equipped with a micro chambered doctor for thin-film slurry coating.

Coats heat-resistant agents such as alumina onto separators. Includes a seasoning function before coating. The dedicated automatic splice mechanism for separator winding reduces core loss.

Standard Specifications

| Applications | Coating heat-resistant agents such as alumina on separators |

|---|---|

| Coating method | Gravure kiss-reverse method |

| Doctor method | Chambered doctor method |

| Adoption | Lithium-ion battery market |

| Options | Corona treater, thickness gauge, inspection system, etc. |

| Machine speed | Max. 150 m/min |

| Substrate width | Max. 1200 mm |

| Drying temperature | Max. 100°C |

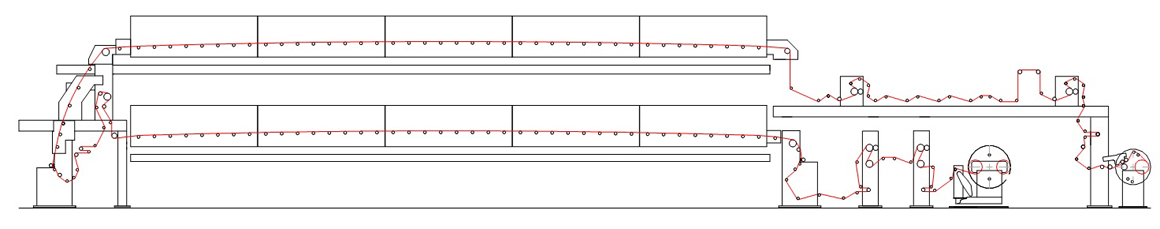

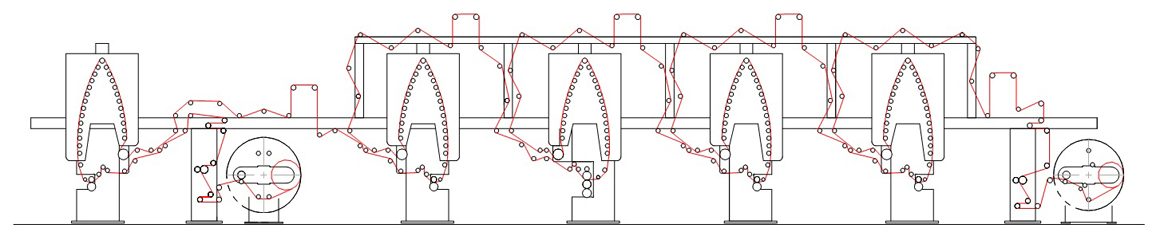

C7-130-2 Lithium-ion Battery Applications

Enables sequential double-sided coating! Equipped with a low-profile dryer for a compact footprint.

Coats heat-resistant agents such as alumina onto separators. The dedicated automatic splice mechanism for separators reduces core loss. Supports sequential double-sided coating.

Standard Specifications

| Applications | Lithium-ion battery coated separators (double-sided) |

|---|---|

| Coating method | Gravure kiss-reverse method |

| Doctor method | Chambered doctor method |

| Adoption | Lithium-ion battery market |

| Options | Thickness gauge, inspection system, etc. |

| Machine speed | Max. 250 m/min |

| Substrate width | Max. 1200 mm |

| Drying temperature | Max. 100°C |

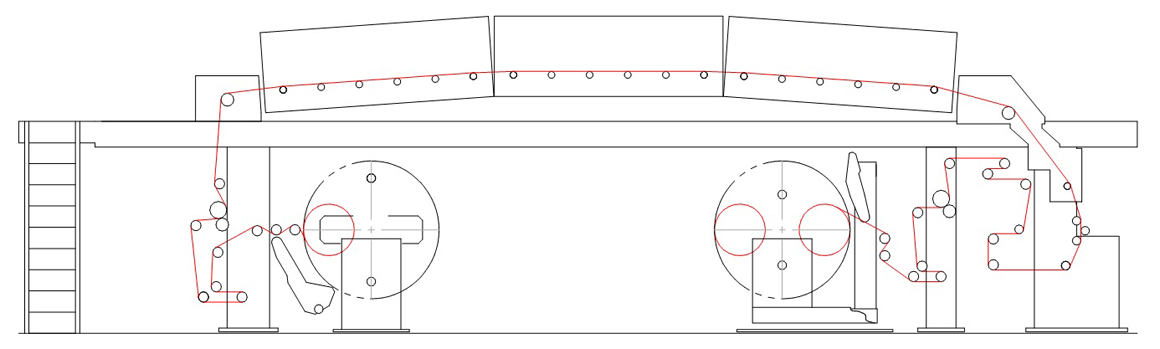

C7-085 Lithium-ion Battery Positive Pole Coating Applications

A sequential double-sided coater—achieves thin, high-speed conductive liquid coating on the cathode while reducing loss.

Equipped with two coating heads and a dryer to enable double-sided coating. Uses a low-profile dryer.

Standard Specifications

| Applications | Double-sided undercoat on cathode aluminum foil |

|---|---|

| Coating method | Gravure kiss-reverse method; stripe coating |

| Doctor method | Chambered doctor method |

| Options | Corona treater compatibility |

| Machine speed | Max. 150 m/min |

| Substrate width | Max. 750 mm |

| Drying temperature | Max. 150°C |

C7-060 Lithium-ion Battery Exterior Applications

Thin-film coating and high-speed operation with a compact system.

Stripe coating matched to electrode width is possible, and high-precision front/back registration supports high-speed operation.

Standard Specifications

| Applications | Cathode undercoat |

|---|---|

| Coating method | Gravure kiss-reverse method |

| Doctor method | Chambered doctor method |

| Options | Defect inspection system |

| Machine speed | Max. 100 m/min |

| Substrate width | 500 mm (consultable) |

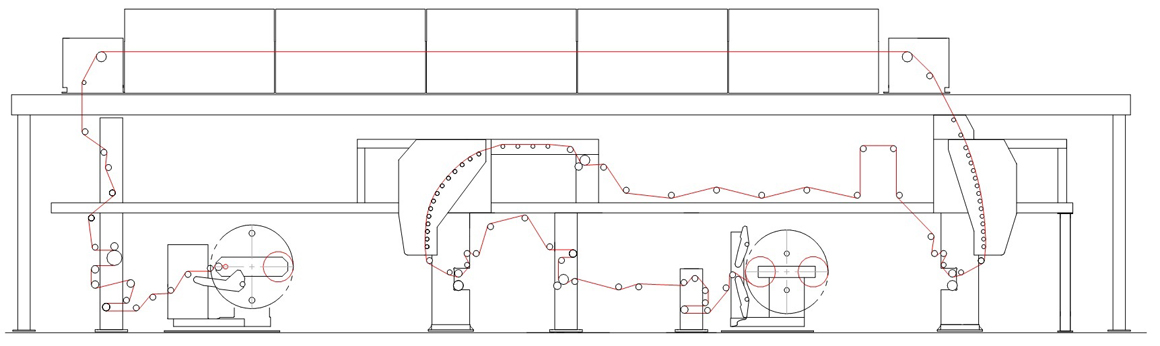

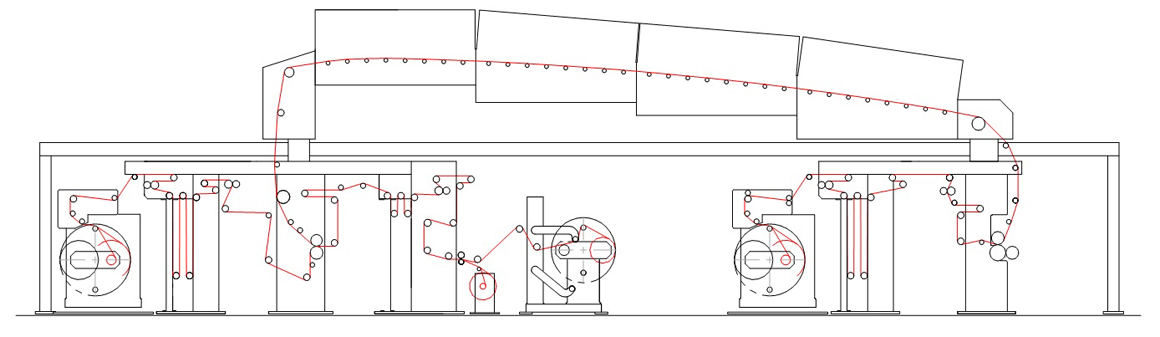

C5-130-2 Lithium-ion Battery Applications

An aqueous coating model for sequential double-sided coating on the cathode.

Achieves thin-film, double-sided passivation coating on aluminum foil. Comes with a floating zone and carrier chain mechanism.

Standard Specifications

| Applications | Double-sided passivation coating on exterior aluminum foil |

|---|---|

| Coating method | Direct gravure method |

| Doctor method | Chambered doctor method |

| Options | Defect inspection system, corona treater, etc. |

| Machine speed | Max. 150 m/min |

| Substrate width | Max. 1200 mm |

| Drying temperature | Max. 250°C |

C5-110-5 For Press Through Pack

Adopts a sectional drive for the plate cylinder, improving access to the drive-side area.

Features a carrier-chain function for quick web-through. Web-through is also possible in the printing/drying unit and the floating zone. Plate cylinder drive uses an AC-servo sectional system.

Standard Specifications

| Applications | Press Through Pack printing |

|---|---|

| Coating method | Direct gravure method |

| Doctor method | Open doctor method |

| Options | Defect inspection system, overprinting function |

| Machine speed | Max. 150 m/min |

| Substrate width | Max. 1000 mm |

| Drying temperature | Max. 250°C |

C9-100-5 Ribbon Coater

A culmination of proven technologies, capable of handling thin films, with transport achievements down to 2.5 μm.

Selectable coating heads such as direct gravure and kiss-reverse, plus web-handling technology enables wrinkle-free transport of thin substrates. The hot-melt unit can be equipped with a heating system for the gravure roll and chambered doctor device.

Standard Specifications

| Applications | Thermal ribbon |

|---|---|

| Coating method | Direct gravure, kiss-reverse, gravure offset |

| Doctor method | Chambered doctor (heated type), open doctor |

| Options | Meyer bar, smoothing, defect detection system |

| Machine speed | Max. 500 m/min |

| Substrate width | Max. 1000 mm |

C9-060 For Flexible Substrates

Stable coating even with high-viscosity adhesives.

Equipped with an accumulator to reduce loss during unwind/rewind changeover. The coating section adopts a triple-roll reverse coater, enabling coating thicknesses from 20 μm to 300 μm. Includes an inline laminator mechanism.

Standard Specifications

| Applications | Flexible substrates |

|---|---|

| Coating method | Triple-roll reverse coater |

| Options | Slitter unit, edge-trim rewind unit |

| Machine speed | Max. 20 m/min |

| Substrate width | Max. 560 mm |